Training & employment

GoodVision trains people in the program countries worldwide and creates secure jobs for well-qualified employees. Over 500 men and women work for GoodVision in eleven countries in Asia, Africa and South America. This creates new jobs with prospects, even in regions with poorly developed labor markets.

GoodVision Technician (GVT)

Training as an ophthalmic specialist

- According to a WHO study, there is a global shortage of more than 65,000 ophthalmic specialists.

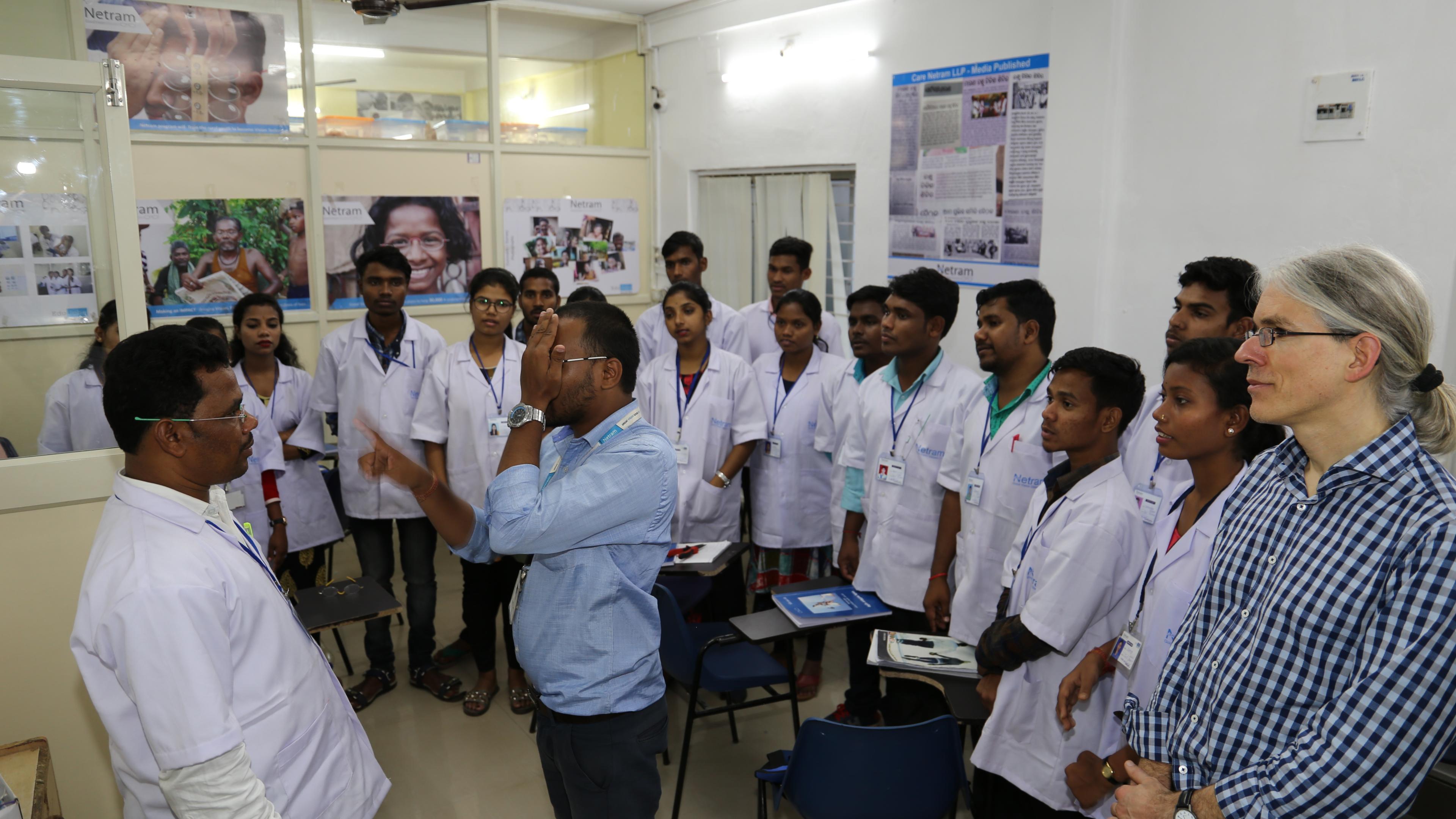

EinDollarBrille e.V. has developed its own training concept for optical specialists. - Training to become a GoodVision Technician (GVT) takes a total of one year. After just a few weeks, trainees are able to carry out a simple eye test and fit glasses safely.

At a glance: The training of our GVTs in India

The future GoodVision Technicians first learn the basics of ophthalmic optics and then complete a 12-week internship in an existing team in rural Odisha. After this initial insight into everyday working life, they receive further in-depth theoretical training. Once it has been verified that the trainees can carry out the eye measurements correctly on their own, a further six-month training period follows directly in the teams working on site. The trainees are instructed by already trained GoodVision Technicians and an optometrist. The optical quality of their work is continuously monitored. More on the topic:

Training as an glasses manufacturer

In many program countries, GoodVision trains people in eyewear production and employs them after they have successfully completed their training. We also attach great importance to offering people with physical disabilities a job. In our production facility in Burkina Faso, for example, we employ Constant, the first blind employee, who has already been working successfully in eyewear production for several years.

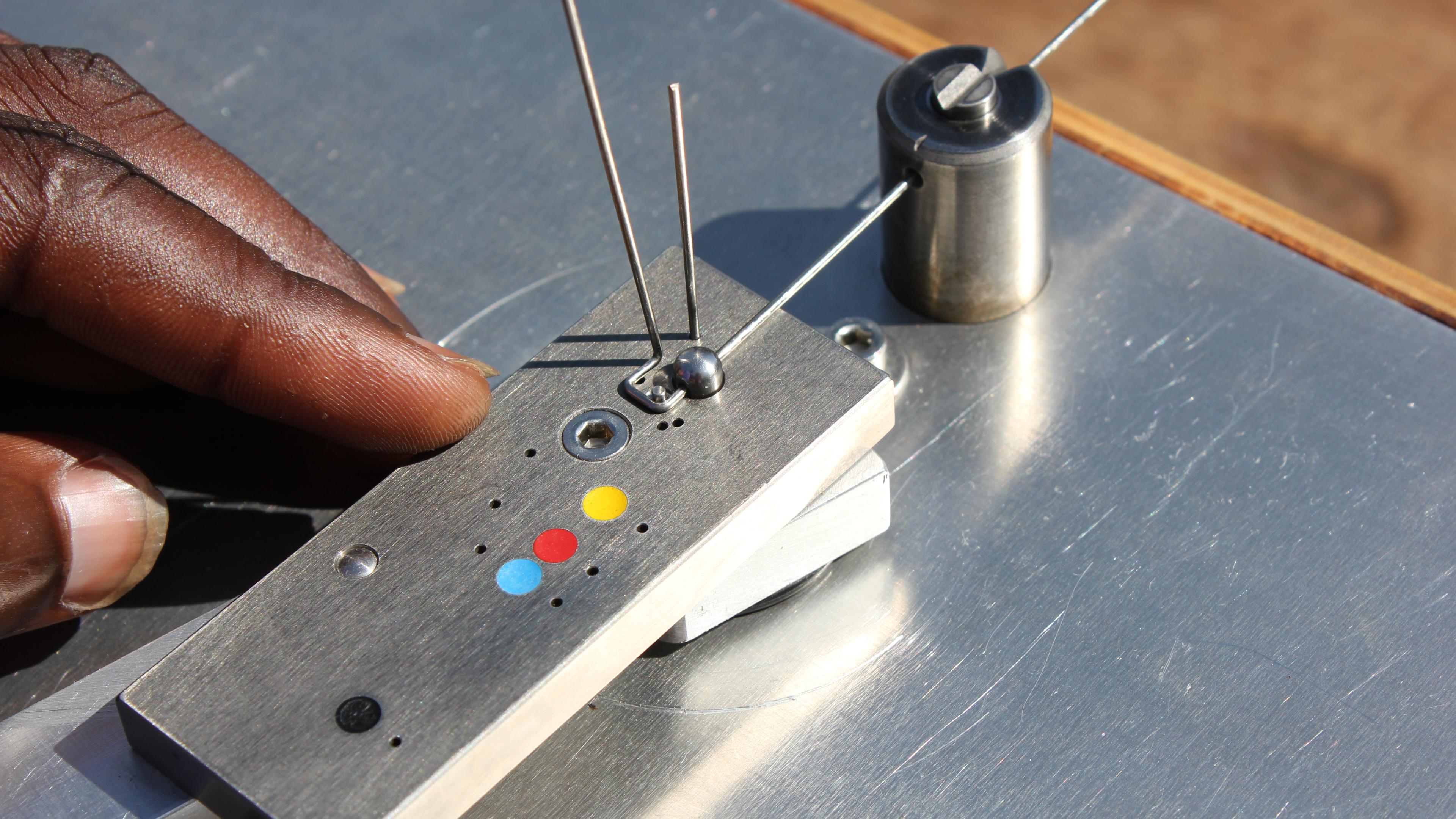

No GoodVision Glasses without a bending machine

We employ around 40 people at our production facilities in Burkina Faso, India, Bolivia and Peru. With their regular salary, they provide for themselves and their families.

We opened our latest eyewear production facility in the Peruvian capital Lima in April 2022. What makes it special is that all team members are single mothers from the surrounding Pueblos Jóvenes, the desert-like outskirts of Lima. Find out more: